Vertical Urban, a UK-based agricultural technology manufacturer, and Microsoft, a global technology company, both believe that CEA (Controlled Environment Agriculture) not only has the ability to play a key role in ensuring food security for future generations, but also believe that they can significantly improve the efficiency and quality of the process.

HORISS Platform Interface

Vertical urban partners with Microsoft AI to develop HORISS

The two companies are collaborating on the development of HORISS, an AI-based CEA control platform.HORISS aims to be an intelligent control system that autonomously monitors and reacts to environmental and physical changes in the growing area, ensuring that the crop is grown to exact specifications, using the precise resources required.

Vertical urban CEO Andrew Littler sat down with Microsoft's General Manager of Data and AI (EMEA), Jens Hansen, to discuss Microsoft's partnership with Vertical urban and how AI has the ability to accelerate CEA's new agricultural revolution and ensure an adequate food supply for future generations.

Andrew Littler

AL: Jens, thanks for hosting us at Microsoft HQ, it was great to sit down and discuss our future plans!

I think it's fair to say that when people hear the name Microsoft, agriculture is not the first thing that comes to mind. Why would a tech-tech company be interested in this agricultural sector?

JH:First of all, I want to say how excited I am about the partnership between Microsoft and Vertical urban.

To answer your question, fundamentally, Microsoft sees technology as a powerful positive force with the potential to create novel solutions to many of humanity's problems. In addition, we believe it is important to ensure that these solutions, in turn, lead to a sustainable future in which everyone can enjoy the benefits and opportunities they bring.

With this in mind, what more important use of technology could there be than to ensure that humankind has the basic resources it needs to prosper now and in the future?

Also, that's the goal of the HORISS platform, and I think we're talking about a very relevant topic today, food security.

AL:Food safety has always been a topic of conversation, and the fact that many local shelves were empty during the lockdown phase of the New Crown Pneumonia pandemic demonstrated to all the vulnerability of our fresh food supply chain in its current form.

Whilst Brexit and the war in Ukraine are probably the biggest reasons we are all talking about food security right now, many other factors will affect our ability to feed the human race.

If you look at drought, climate change, population growth, these are all changing the way we grow and produce food. The fact that we have to grow indoors to meet the demand there has been at the forefront of our thinking.

JH:Ultimately, it sounds like we need to prepare for the future, including population growth and other factors that may be out of our control, right?

If you're following this space, take a look at what vertical urban is doing and what do you think some of the key enablers are that you're driving with the company?

AL:We see this as a complete project. We can provide the perception, we can provide the software (HORISS), we can provide the hardware to make all these future farms the providers of our food.

JH:I know our team is very excited to be working with your company. So basically, the HORISS software, if I understand correctly, monitors the growth process of the plants and adjusts the environmental parameters, which is somehow intelligent?

Jens Hansen

AL:Yes, Jens.I mean, essentially, if you look at AI technology using sensors, camera vision, and algorithms, what it's effectively doing is monitoring the performance of the crops and making sure that they're getting the right dosage of nutrients, the right amount of light, and all of the other things that they need to do to achieve the desired growth.

Microsoft's AI will excel in the processing and analysis of the vast amounts of data collected by the HORISS system. The aim is to identify trends and patterns in the data that will allow us to not only recreate the conditions that produce the most desirable final crop, but ultimately to automatically identify and remedy problems that occur during the growing cycle, and, crucially, to minimise the impact on the final harvest before they are detected by humans.

The more data HORISS collects and incorporates into its models, the earlier problems can be identified and the more effectively they can be corrected in a timely manner, reducing wasted resources and even whole crop disease.

In short, we're looking for an optimisation that maximises crop yields while minimising resource use, and AI helps to achieve this. How do you think Microsoft will help us achieve this in the future?

JH:Good question. Microsoft is a platform company, and we've always tried to lead the way in terms of new developments in these areas, including a variety of AI technologies, from vision to object recognition to other sub-areas of the field. But I think ultimately it's also our responsibility to partner with companies like yours to bring it to market together and make that happen, and that's why I'm excited to see partnerships like ours come to fruition.

So far we've talked about meeting the raw yield side of things, but in most cases the final crop needs to taste great too to be classed as a success. We all like tasty food, right?

Machines and computers obviously can't taste crops directly, that's the domain of humans, so it's vital to find other ways to make sure that whatever we grow tastes the way we want it to.

This is a great example of the specific challenges that HORISS and Microsoft AI can take on, isn't it?

AL:Indeed, creating a flavour alternative is the most challenging and interesting part of the process. In other words, can we find a set of growing conditions that will guarantee a tasty harvest? Furthermore, will we be able to know the exact impact of these variables?

In the HORRIS-controlled CEA system, the conditions experienced by each crop during its life cycle will be recorded in detail. If we mark the results as desirable and undesirable, these datasets can be combined and analysed by Microsoft's artificial intelligence. Over time, the system will be able to calculate the growing conditions that will ensure not only the optimum yield of the crop, but also that it looks and tastes satisfactory.

In the end, only humans can decide if the last part is successful or not.

JH:Of course, it's important to note that while AI is a powerful tool, it's not a panacea, nor is it a complete replacement for humans; if anything, it will take on more repetitive and intensive analytical tasks, leaving humans to do other, more complex tasks for which AI is not suited.

For example, if we look at the relatively simple concept of picking an apple from a tree. Humans can easily find the scattered branches and leaves, assess maturity, and adapt to the strength of the stem. The fruit is easily picked from the tree, many times without even looking. AI-controlled robots have a hard time with this task because there are too many variables that don't fit the pattern; apples may be hidden behind branches or leaves; apples may look ripe from one direction and not from another; two apples that look the same may have different stem strengths, and so on.

AL:Good point, I think it's easy to get swept away by what we see in films compared to what might happen in the real world!

One of the reasons CEA is particularly well suited to AI control is to make it easier for sensors to locate and eliminate many complex variables. This makes it much easier to collect valid data and truly useful outputs.

What do you see as the ultimate goal of Microsoft's partnership with Vertical urban, HORRIS and the wider CEA industry?

JH:We want to see a future where all humans have a reliable and plentiful supply of food that is both tasty and nutritious. All with less waste and minimal environmental impact.

AL:Yeah, I don't think there's enough talk about food waste, I remember seeing a statistic recently that 19 per cent of lettuce grown in the UK ends up going to waste, which is crazy.

The big supermarket chains are investing heavily in CEA, especially in vertical farms, to ensure supply. It will also be interesting to see how cleverly they utilise them to reduce waste.

They (supermarkets) are already harnessing the power of AI to predict shopper behaviour and control their sourcing and distribution networks. Integrating AI-controlled smart vertical farms into the supply chain will allow produce to be grown only on demand, which will have a huge potential impact.

JH:Indeed ...... It's definitely good to see less produce going to waste! Our conversation really opened my eyes and I look forward to learning more as time goes on.

The future of vertical farming is becoming increasingly clear, using artificial intelligence and visual recognition technology to monitor farm environments and plant growth to gain 100 per cent control over the environment and ensure that food is grown in the most opportune conditions, guaranteeing yields with great appearance and flavour, and aiming for a sustainable circular economy.

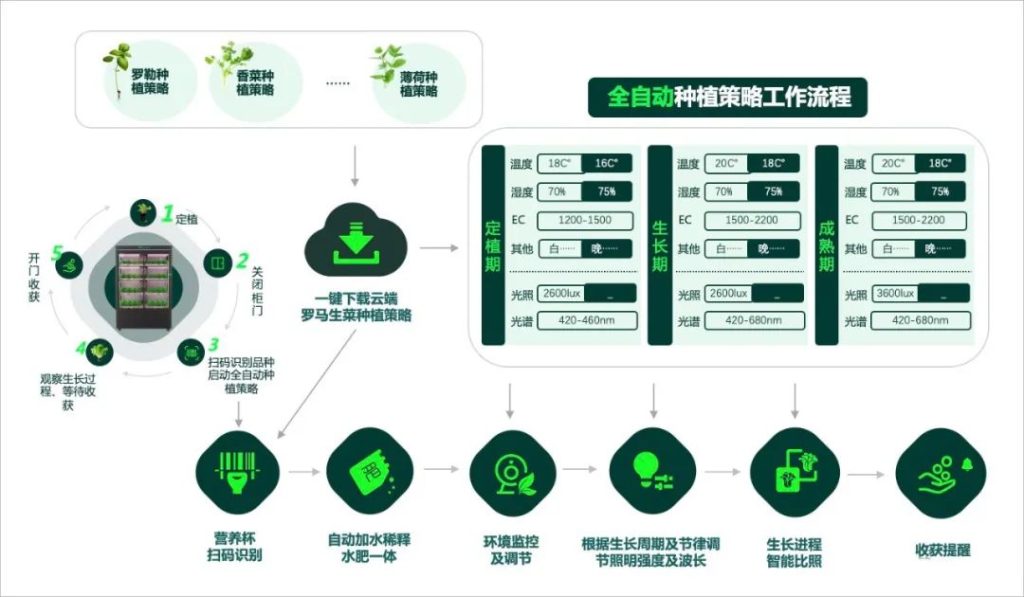

VegeSense Intelligent Cultivation Control Platform

This is in line with VegeSense's philosophy, which is a perfect blend of software that not only fully automates planting but also optimises plant growth using artificial intelligence algorithms driven by the fact that every day the VegeSense Smart Plant Cabinet learns, and that each plant is unique and requires a specific combination of light frequency, climate, nutrients and growth cycle. specific combinations of light frequency, climate, nutrients, and growth cycle. Over time, we will collect data and learn how to improve our growth to create the best tasting and highest yielding product possible.

Recycling is in our DNA. Everything we do is in line with a zero-waste policy, with 5% recycled water, 0 chemical pesticides, carbon and oxygen absorption, fewer miles travelled to transport food, less food waste, and unused vertical space repurposed. And built on a circular economy, growing more with less.